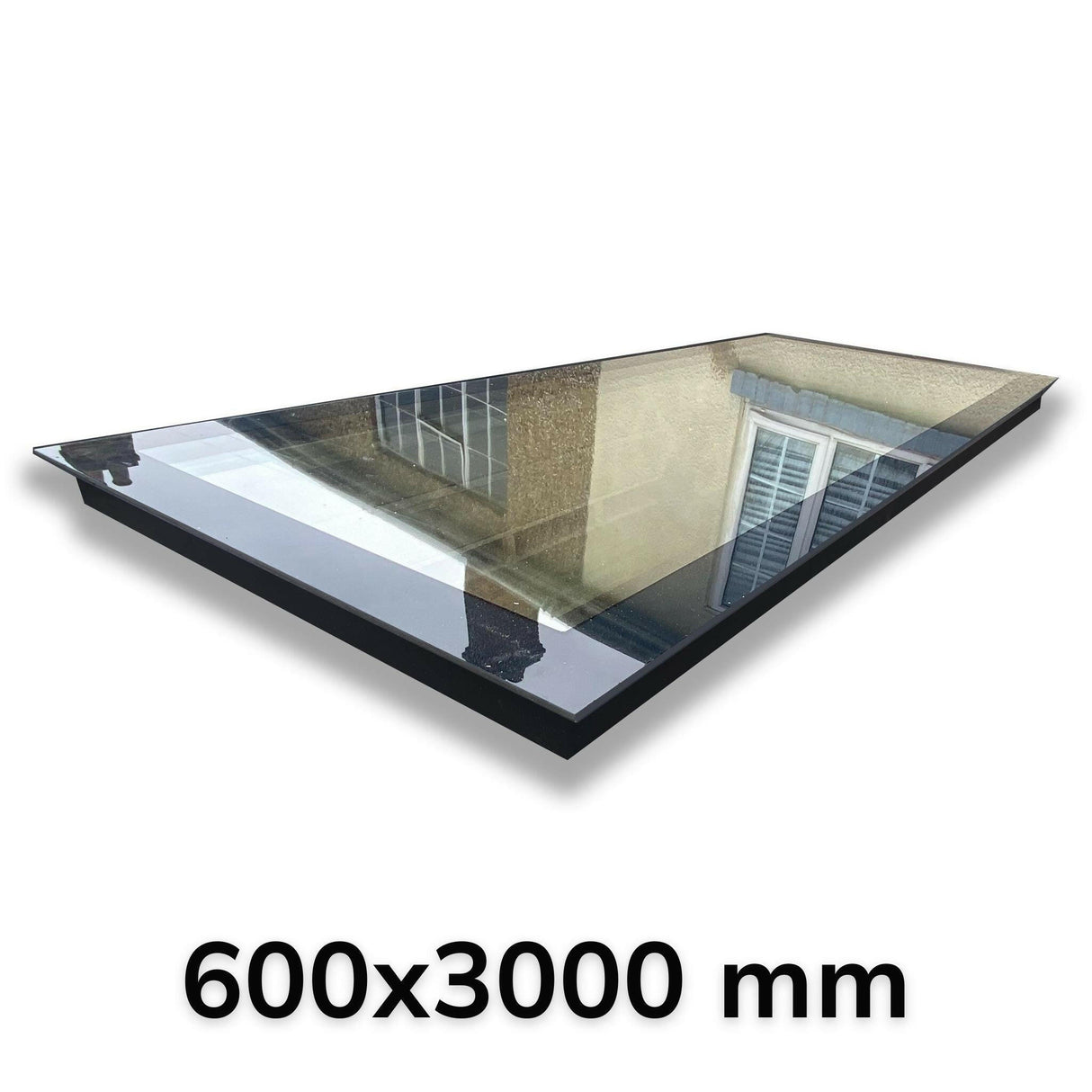

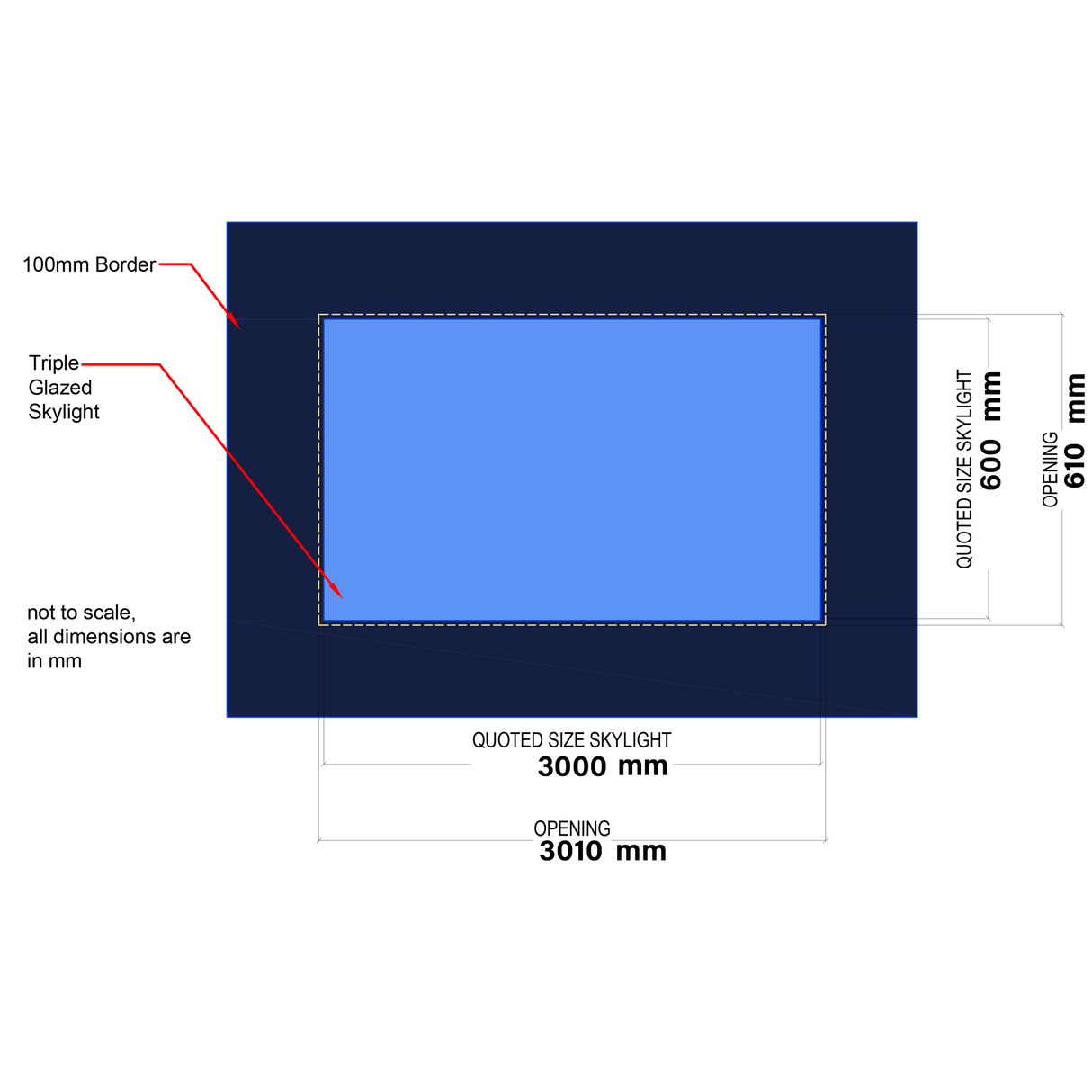

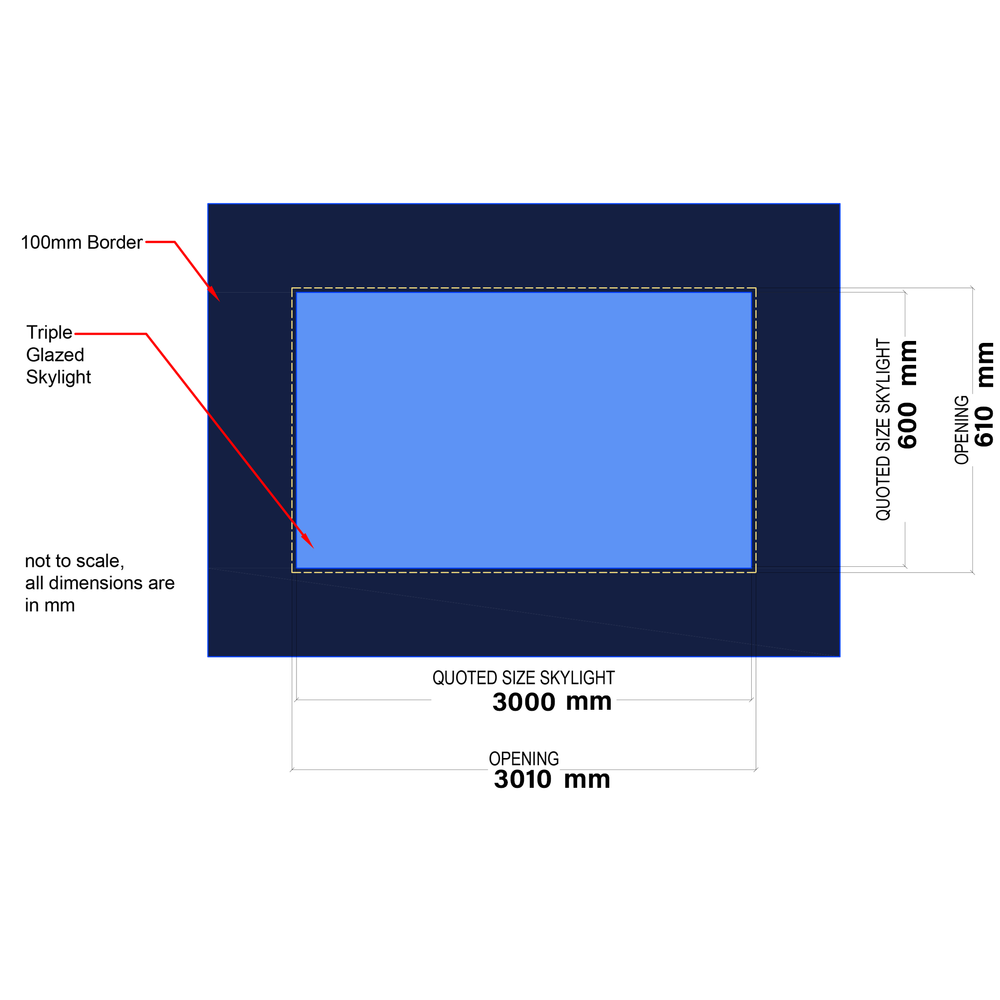

600 x 3000 mm LD Frameless Triple Glazed Flat Roof Skylight

600 x 3000 mm LD Frameless Triple Glazed Flat Roof Skylight is Available.

| Loading... | Loading... |

|---|

Key Highlights

Key Highlights

- Superior Thermal Efficiency – Triple-glazed with a U-value of 0.7 W/m²K, featuring 90% argon-filled cavities and thermal super spacer technology to minimise heat loss and enhance insulation.

- Toughened Safety Glass – Built with 6mm toughened glass (up to 8mm for larger sizes), ensuring durability, strength, and compliance with BSEN1279 standards for maximum safety.

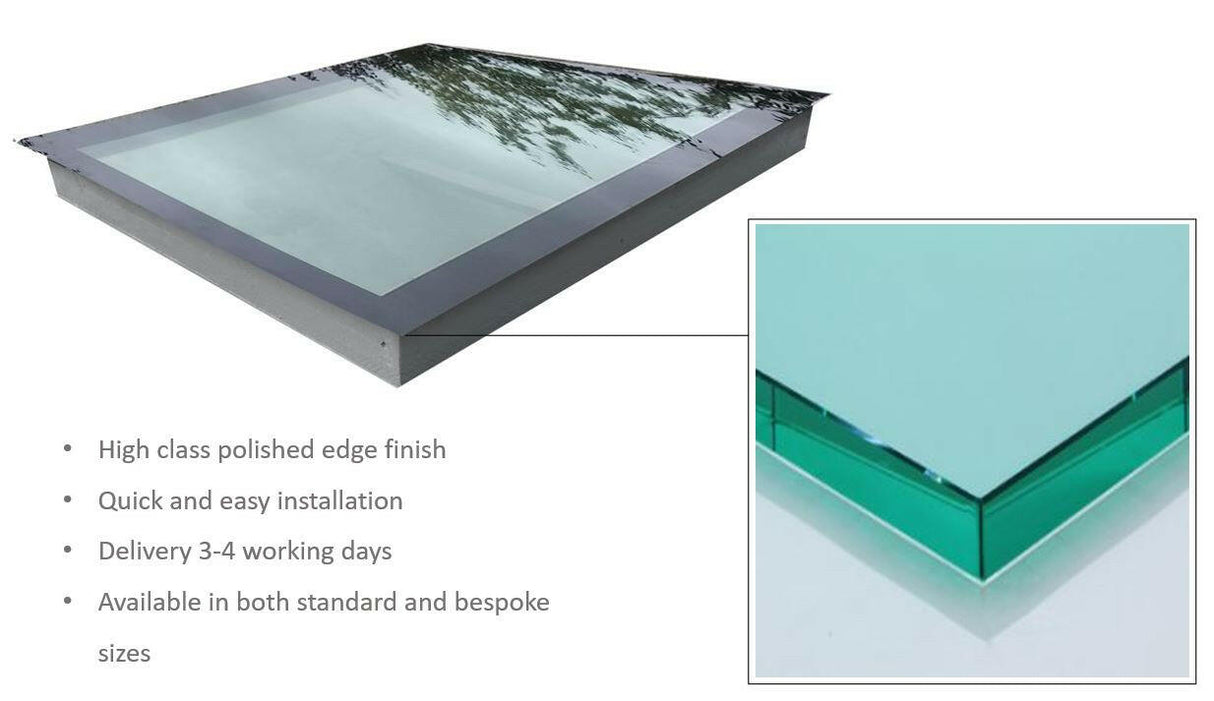

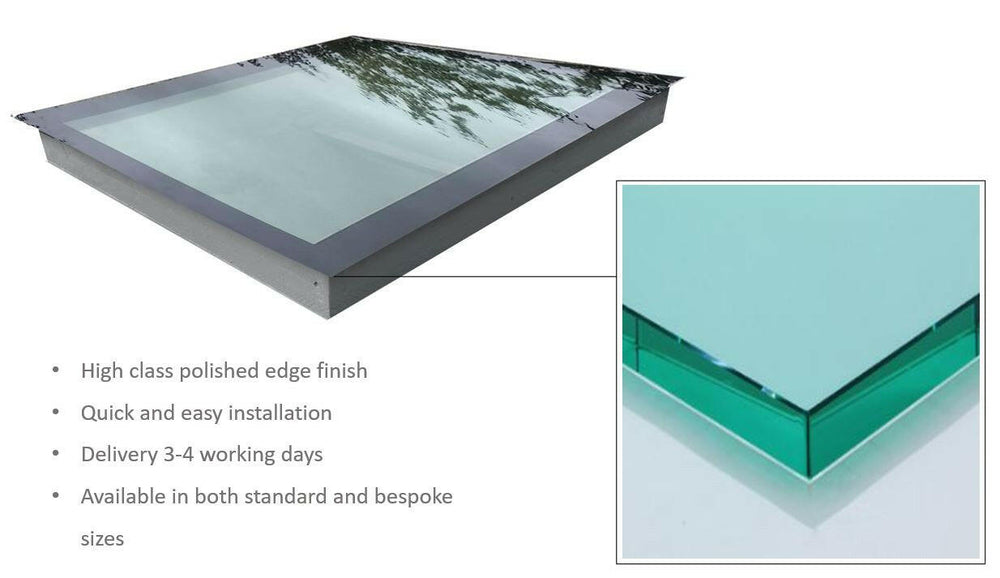

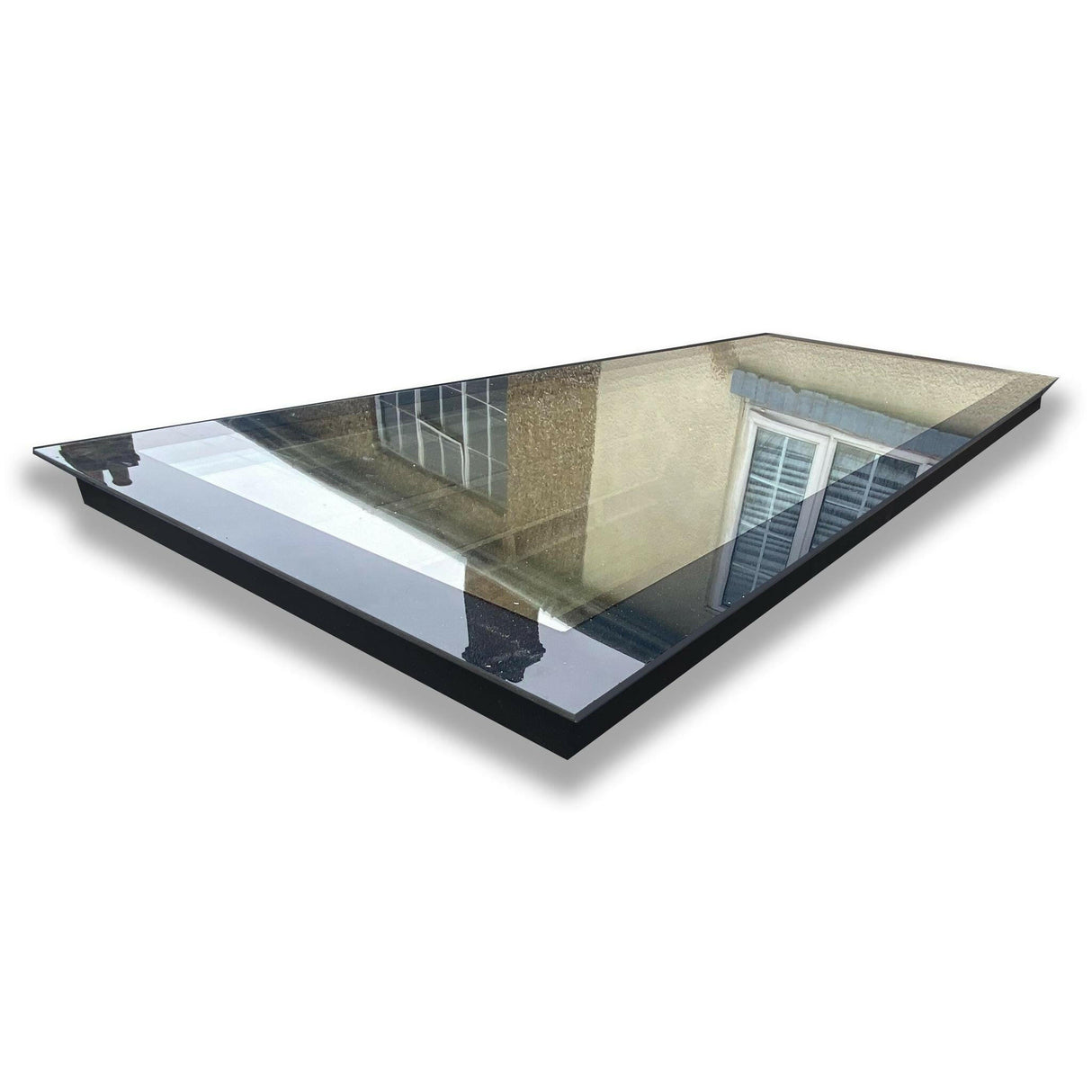

- Modern and Sleek Design – Polished edges and frameless construction create a clean, contemporary aesthetic that enhances natural light and complements modern interiors.

- Natural Light Optimisation – Self-cleaning glass with 72.6% light transmittance brightens interiors while maintaining clarity and reducing glare, improving overall visibility and ambiance.

- Easy Installation and Longevity – Designed for flat or pitched roofs with a simple installation process, supported by a 25-year manufacturer’s warranty (with the purchase of our Structural Glazing Tape) for long-term peace of mind.

Description

Description

Illuminate your living space with our robust frameless skylights made from toughened safety glass. These skylights, available in various standard sizes, provide superior thermal insulation thanks to their design. Ideal for installation on flat or pitched roofs, our skylights are perfect for brightening up your home. Crafted from toughened safety glass with a premium polished edge finish, our skylights feature triple-glazed units filled with Argon gas and equipped with thermal super spacer technology, ensuring outstanding thermal efficiency and light transmission.

FEATURES:

TOUGHENED SAFETY GLASS: Every skylight comes with 6mm toughened safety glass with 0.7 w/m²K U-Value for exceptional durability and compliance with BSEN1279 standards.

ARGON GAS INSULATION: Enhanced thermal insulation and light transmission are achieved through thermal super spacer technology.

MODERN DESIGN: Adds a contemporary flair to your décor and increases natural light.

SIMPLE TO INSTALL: Designed for those with DIY experience, our skylights can be seamlessly integrated into flat or pitched roofing systems, making them an ideal choice for various roofing projects.

Made in the UK

Keep in mind, your 25-year warranty is only valid with the purchase of Structural Glazing Tape and if you've supported the bottom pane glass with timber battens in line with our installation guide!!!

Specifications

Specifications

- Internal Size: As Quoted in the Product Title

- Glazing: Triple Glazed,

Top Layer: 6mm Toughened Safety Glass (or 8mm depending on skylight dimensions)

Air Gap: 15mm 90% Argon Filled

Middle Layer: 4mm Thermally Toughened Glass (or 6mm depending on skylight dimensions)

Air Gap: 15mm 90% Argon Filled

Bottom Layer: 6mm Low-E Toughened Glass

- Weight: 90 kg

- U-value: 0.7 W/m²K

- G-Value: 5.19 (51.9%)

- Self-Cleaning Glass

- Glass Type: Clear Tint

- Pitch: up to 45 degrees

- Thermally Efficient

- Argon Gas Filled

- Visible Light Transmittance: 72.6%

- Visible Light Reflectance: 16.2% in; 15% out

- Solar Energy Reflectance: 27.5%

- Quick and Easy Installation

- Strong, Secure and Durable

- Step By Step Installation Guide

- Warranty: 25 Years Manufacturer Warranty

Made in the UK

Installation Guide and Video

Installation Guide and Video

Installation Video

Manual Handling Guide

Keep in mind, your 25-year warranty is only valid with the purchase of Structural Glazing Tape and if you've supported the bottom pane glass with timber battens in line with our installation guide!!!

Safety and Certification

Safety and Certification

- All of our products are fully compliant with British Standards & Building Regulations and carry all necessary Safety Certifications.

- They are also CE marked, demonstrating compliance with applicable EU directives and standards for products distributed within the European Union.

- Certified Toughened BS EN 12150

T&C's & Warranty

T&C's & Warranty

Should you discover a crack in the glass upon delivery, it is essential that you notify us immediately. Failure to report the damage within 12 hours of delivery will invalidate your eligibility for a return or replacement. Please contact us promptly to address the issue.

We offer 25-year warranty on the seal of the unit.

Keep in mind, your 25-year warranty is only valid with the purchase of Structural Glazing Tape and if you've supported the bottom pane glass with timber battens in line with our installation guide!!!

Additional Resources

Additional Resources

Frameless Spec Sheet

Manual Handling Guide

Delivery and Shipping

Delivery and Shipping

ECONOMY NATIONWIDE SHIPPING: Delivery is typically within 2-5 working days for most standard sizes and 6-10 for the other sizes (exact delivery time is available on the checkout page).

NEXT DAY DELIVERY: Available in select postal codes. Please consult our shipping terms for eligibility.

Keep in mind, your 25-year warranty is only valid with the purchase of Structural Glazing Tape and if you've supported the bottom pane glass with timber battens in line with our installation guide!!!

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Guidelines for Installation and Best Practices

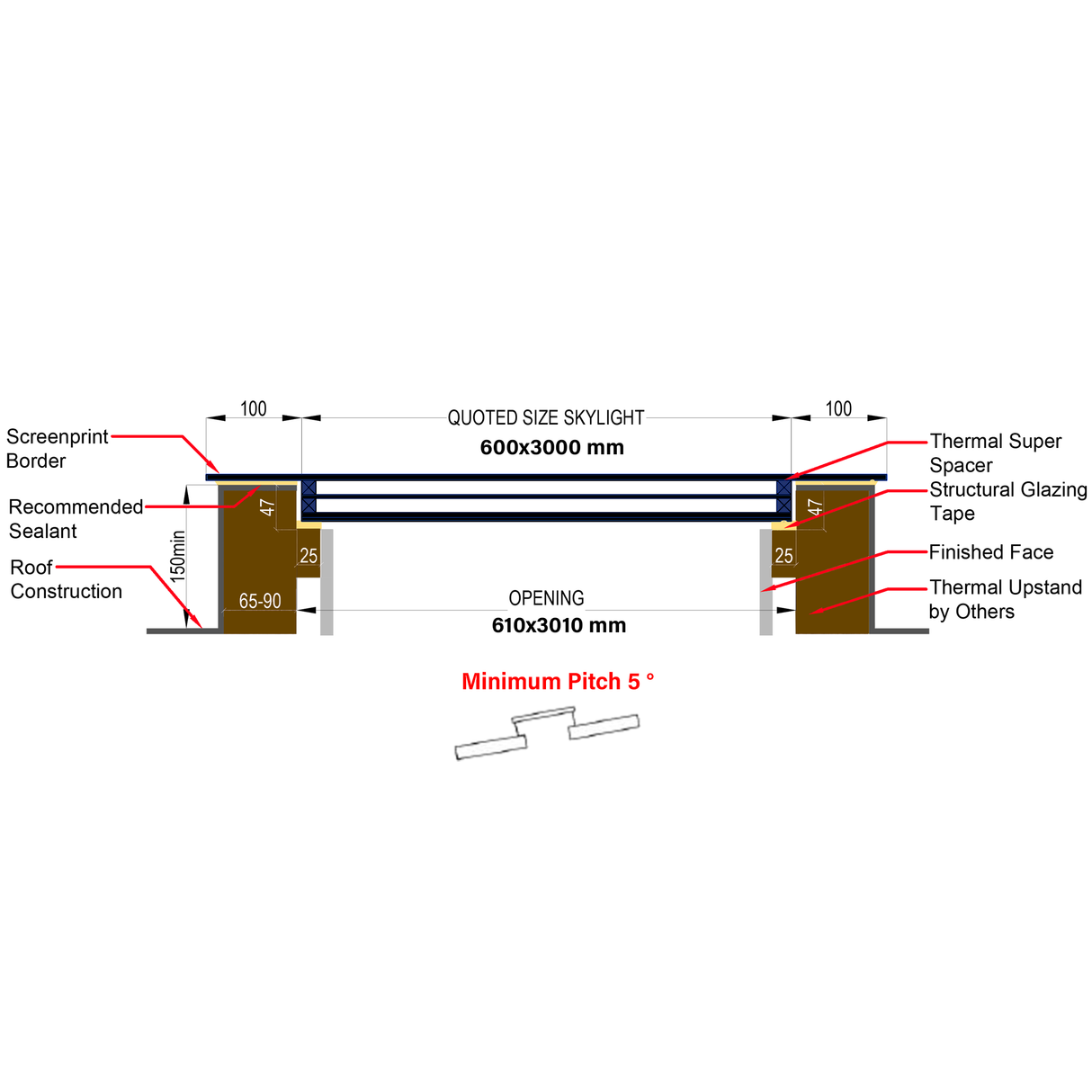

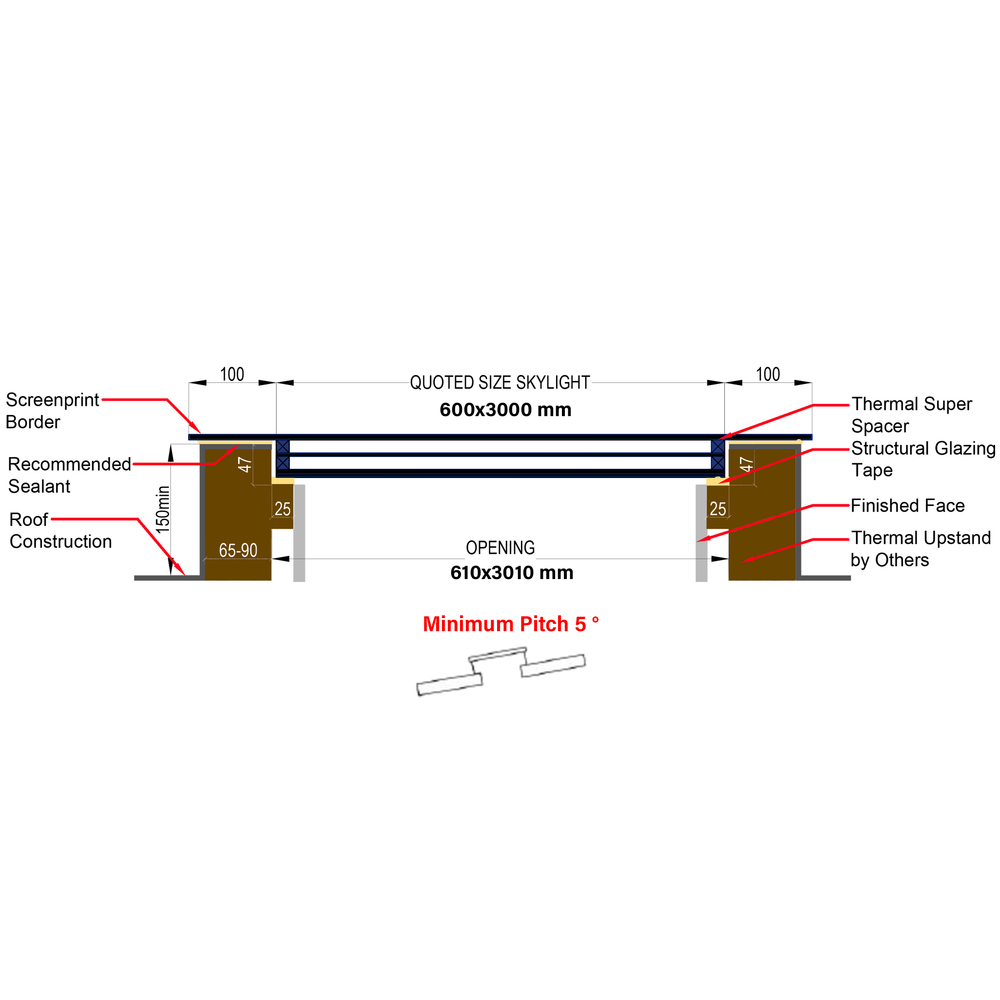

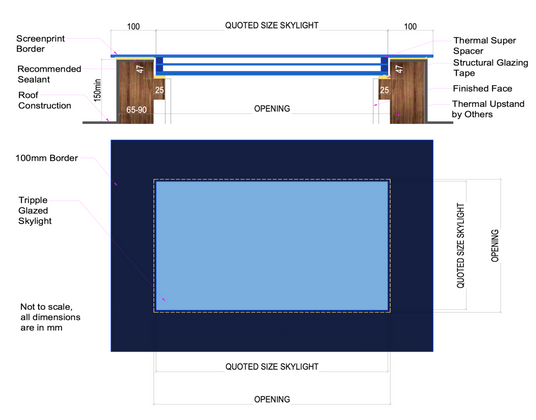

Measurement of Internal Dimensions and Structural Opening:

Please be aware that the quoted size is the internal size of the unit which when measured should be taken from upstand to upstand plus an addition of 10 mm in width and length to allow to skylight to fit freely in the structural opening (e.g. a 1000 x 2000 mm skylight would require a structural opening of 1010 x 2010 mm from upstand to upstand)

Upstand Framework Construction and Installation Tips:

For the construction of the upstand that the skylights overhang sits on we would suggest using 4 x 2 inch timbers and 2 x 1 inch or 2 x 2 inch timber batten running on the inside where the bottom pane of glass rests.

We recommend the upstand to have a minimum of 6 degree pitch (preferably on the short side) to avoid water pooling in the middle of the unit which would mean roughly 10 cm for every 1 linear meter of skylight. For instance, a 1000 x 2000 mm unit would require one end of the upstand to be 10 cm higher than the other if skylight pitched on the short side and 20 cm higher if pitched on the long side.

Make sure a foam rope is placed on top running all along the timber batten eliminating any unevenness and aiding in the distribution of the weight of the skylight evenly across the surface.

Apply black weatherproof sealant generously along the surface of the upstand where the overhang sits to fully seal the unit and guarantee protection from the elements.

Please make sure you only use silicon or polyurethane sealants.

Do not use any acrylic sealants as these could react chemically with the units finish material and could subsequently compromise the seal of the unit.